We are the largest technology-enabled platform for serial timber production

We are committed to transforming the construction industry sustainably through our scalable and efficient approach. With our climate-neutral buildings and smart digital building systems, we are significantly driving the energy transition in the building sector.

We make Germany's building sector climate-neutral. Over 80% of our sustainable buildings are produced in-house.

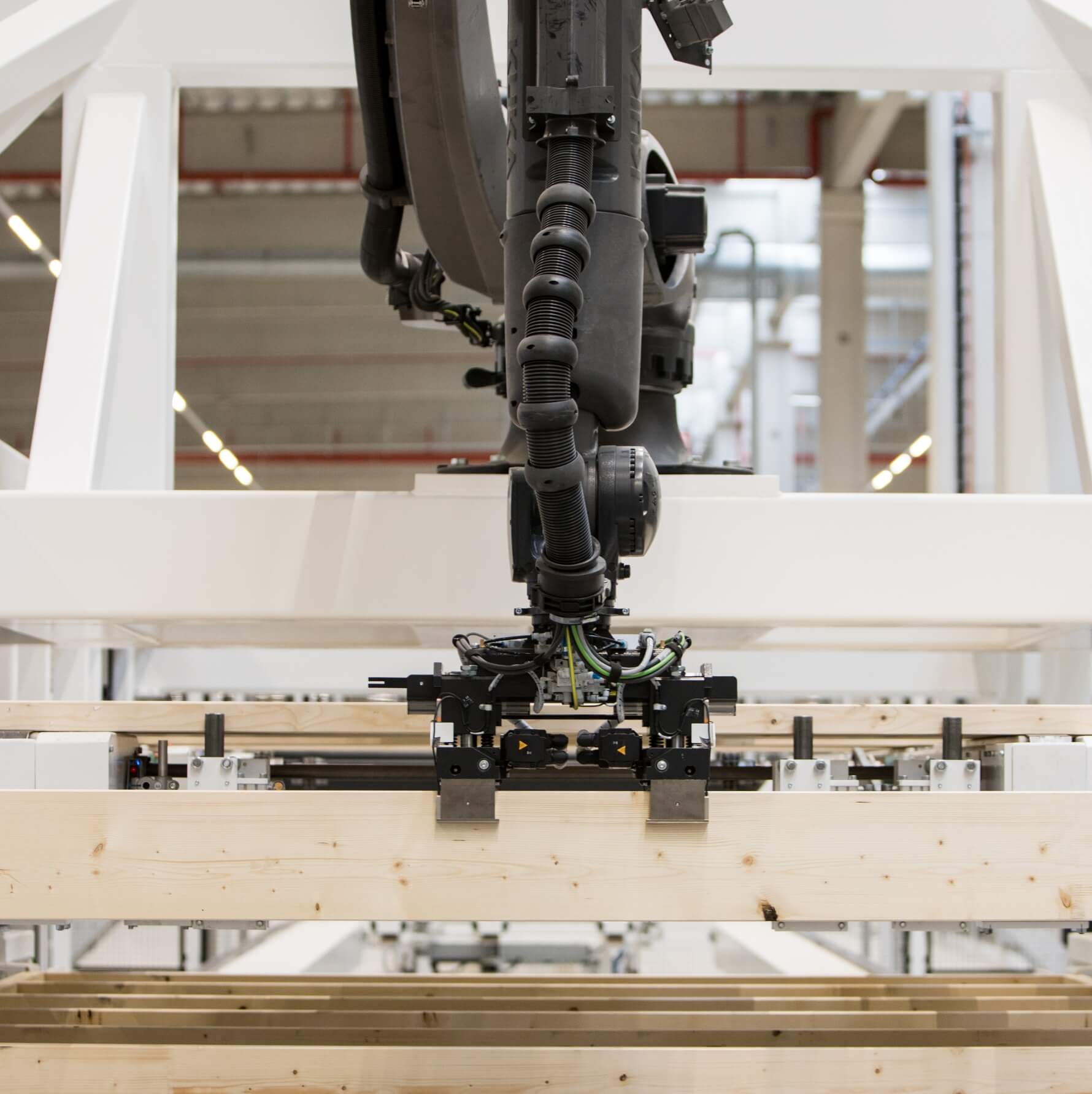

Serial timber construction

We construct multi-family houses, schools, kindergartens, and public buildings using wood. Through digitized processes and serial production, we enable the highest precision and short construction times of just under 3 months. This allows us to produce highly efficient sustainable buildings with maximum planning reliability and cost certainty.

Serial renovation with wood

We energetically renovate Germany's building stock through scalable and efficient serial prefabrication. For exterior renovations, we focus on prefabricated roof trusses and wooden facades, while for interior renovations, we focus on kitchens and bathrooms.

Serial energy optimization

We optimize our new buildings and existing structures with sustainable energy generation systems such as heat pumps and photovoltaics. This results in buildings that generate more energy than they consume. To continuously improve efficiency, we also take over energy management. More on serial energy optimization.

We transform the world's largest industry – and build a better tomorrow.

We create living space for Germany

The housing shortage in Germany is one of the biggest social challenges of our time. Over 700,000 affordable homes are missing, and innovative scalable solutions are needed. We have developed a digitized, serial construction process that allows us to efficiently create resource-efficient, livable, and affordable housing in record time.

We make Germany's buildings climate-neutral

The conventional construction industry is one of the largest contributors to greenhouse gas emissions worldwide. The consequences of the climate crisis require radically new approaches. Our serial prefabrication is efficient and energy-saving through digitalization. We utilize wood as a renewable and recyclable resource, and our climate-neutral residential buildings generate more energy than they consume.

Decarbonizing the building sector is the essential key to achieving climate goals. We at NOKERA are committed to transforming construction sustainably.

Digitizing construction and renovation through BIM models and smart data utilization

Through serial prefabrication, we scale the construction and renovation of multi-family houses. We have developed an innovative and digitized process for this purpose: For each construction project, a digital twin is created as a data source, which maps the fully digital process chain throughout the entire production process. Work and assembly plans are automated, and the ERP system controls the entire project.

Serial prefabrication makes construction and renovation highly efficient

We produce over 80% of all required components at our vertically integrated production sites. Each individual system component is prefabricated serially and standardized for construction and renovation purposes. This speeds up the production processes and allows us to deliver turnkey multi-family houses in less than three months.

Building and renovating in an environmentally friendly manner through the use of wood

Our primary building material is certified wood (PEFC), sourced primarily from Germany - a renewable material that significantly reduces CO₂ emissions and energy consumption. By using sustainable and certified wood, we drastically reduce construction waste, and buildings become up to 95% recyclable.

The result: buildings that generate more energy than they consume

For all new construction and renovation projects, we offer the installation of photovoltaic systems, heat pumps, and comprehensive energy management. This results in energy-efficient houses according to the KfW-40-NH standard, which generate more energy than they consume and are certified with the DGNB Gold Standard. Sustainalytics has rated us as one of the top 3% ESG companies worldwide.

The centerpiece of NOKERA: the world's largest factory for serial timber construction

Located in Stegelitz near Magdeburg, our Green Construction Factory spans nearly 120,000 square meters and will have production capacities for building and renovating up to 30,000 housing units per year. Even our production is consistently sustainable: our Green Construction Factory is certified with the DGNB Gold Standard and is an efficiency house according to KfW 40 NH.

Learn more

At NOKERA, the world of tomorrow is being built today.

> 20,000

commissioned housing units

3

months total construction time thanks to industrial production processes

> 1,000

employees

~ 1.5 million

square meters of living space

4

state-of-the-art production facilities in Germany